RESEARCH AND ANALYSIS

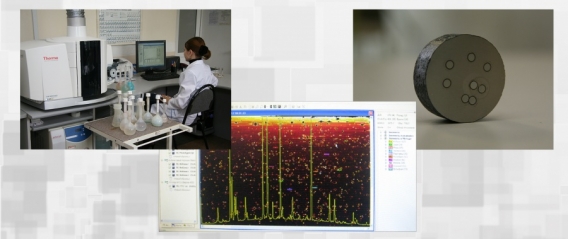

VBM'S CENTRAL LABORATORY

Unique knowledge and skills of personnel along with the contemporary analytical equipment provide a solid foundation for VBM's Central Laboratory to conduct in-depth inspection of several hundreds of types of materials as well as semi-finished products and finished goods.

Our Lab is equipped with:

- inductively coupled plasma atomic emission spectrometer for chemical composition study;

- atomic absorption spectrometer;

- spectrophotometer;

- carbon analyzers;

- viscometers;

- penetrometers;

- devices for determining the flash point and dropping point;

- devices for determining particle size distribution;

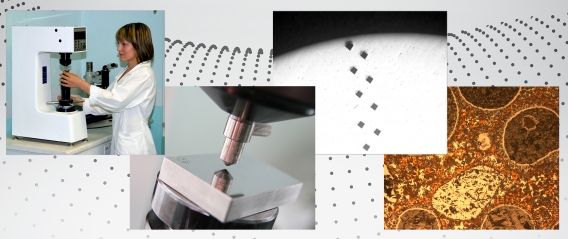

- wide range of hardness testing machines;

- optical microscopes;

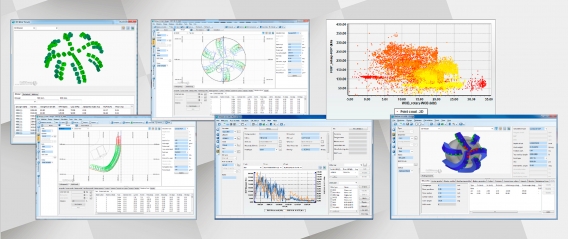

- image analyzer;

- laboratory furnaces;

- analytical balances;

- mechanical properties testing machines, etc.

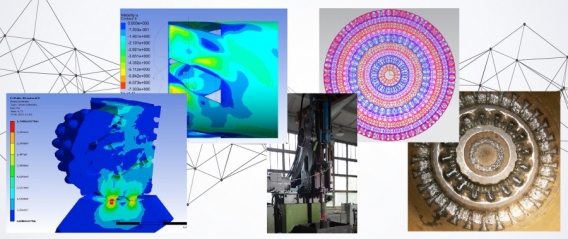

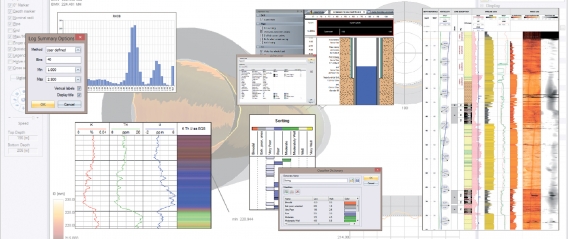

Not only does the laboratory provide precise evidence of quality compliance at each stage of the manufacturing process, one of its routine yet crucially important functions is analysis of used drill tools, this allows our engineering team and manufacturing subdivision to receive comprehensive feedback thus enabling continuous improvement.